Consumable Plasma Cutters - Pros & Cons

A plasma cutter is a device, which can cut through metal using super heated gases emitted from a nozzle. These cutters can apply 30,000 Fahrenheit of heat through a tightly focused emission, cutting into the thickest metals in moments. These devices are also known as plasma torches.

Uses of Plasma Cutters:

Plasma cutting works well with steel and non-ferrous materials less than 1-inch thick. Car manufacturers, customized auto body shops and construction companies all use plasma cutters. Locksmiths also useplasma cutters. Consider these factors before purchasing a plasma cutting machine:

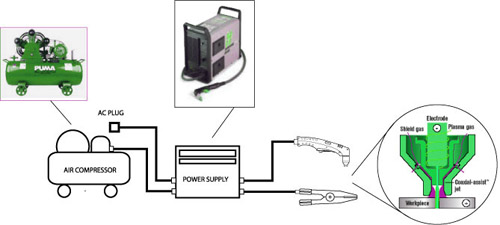

How Plasma Cutter Function:

Gases like nitrogen, argon or oxygen go through a narrow nozzle. Inside, there is an electrode, which pumps electrical current into the gases in a process known as ionization. Due to ionization, the atoms in the gases jolt around with stimulation. The atoms divide the electrons from the nuclei and thereby formplasma. This activity causes an enormous surge of energy, which can be utilized in the toughest industrial components.

Selecting a Plasma Cutter:

Compared to traditional torches, plasma is faster than other gases and does not depend upon highly flammable gases. There are now a number of plasma cutters or torches for below $1,000. EVERLAST offers one such plasma cutter with its own compressor, priced at $998.75.

Before buying a plasma cutter, bear in mind these three important points.

* The thickness of the metal.

* The maximum thickness normally subjected to cutting.

* The speed of operation or the timeframe for completing the job.

Finally, make safety a top priority. At EVERLAST, that commitment to quality and personal protection is a necessity.