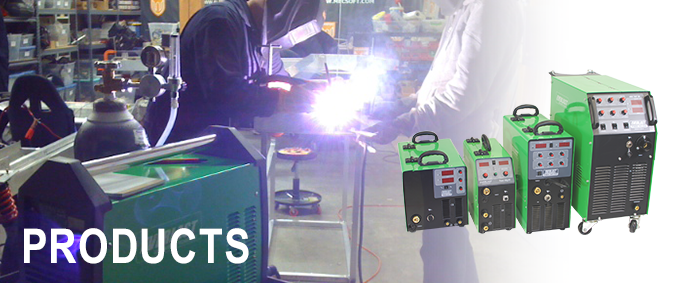

Power i-MIG 353DPi

The Power i-MIG 353DPi features the latest in inverter based, pulse MIG technology. This welder is ideal for welding aluminum and bronze brazing activities in the automotive industry. It features two types of synergic pulse: Single and Double. The Single Pulse is perfect for control heat and wet in and burn through of heat sensitive metals where HAZ issues are a concern, such as the auto-body businesses where new alloys require special welding and brazing processes to repair frames and panels safely and reliably. With Single pulse, increased production speed welds are possible without over-melting or the metal, allowing for out of position welding of aluminum. Double pulse features a "stair-stacked" pulse which features the ability to stack the single pulse into two basic layers, which helps to form a "stack of dimes" TIG look in the weld. This is ideal for welds where appearance and strength count equally and is required for best possible appearance without resorting to TIG. The unit can also be used in a synergic MIG mode without pulse and a basic non-pulse, non synergic mode as well, where full control over all parameters are possible manually. To prevent crater cracking and cold starts the unit has several features which include slope up, hot start, down slope. Pre and post flow are standard features as well, which help prevent porosity at the beginning and end of welds where it is common to develop weld flaws. If you find a program you like in a manual setup mode, you can easily save it with the capacity to store 9 major programs. The unit is programmed with a possible 40 different, well designed and tested synergic programs for standard and pulse MIG operation. Companies and individuals who are looking for the consumate professional MIG machine will appreciate the ability to fine tune the arc even while in synergic mode, a hallmark characteristic of all Everlast synergic capable MIGs. The Power i-MIG 353DPi brings the price significantly down from competitor models, making this one of the affordable and capable pulse MIG welders on the market. There's no longer any need for a company or individual to spend $10,000 or more on a special welding machine to repair modern alloys. The machine can be used to weld aluminum, bronze, steel, or stainless. When welding aluminum, the standard gun works well, but an optional spool gun or push-pull gun can be used to feed wire from .030" to .062" in diameter using the syngeric pulse feature. The 60% duty cycle at 350 Amps proves this unit is a serious heavy-weight contender. If you really want to compare to other units in this class, check out other manufacturer's duty cycle at maximum output. Some can only operate at maximum output for 10 seconds. Others are only at 10% at maximum output. Now when you consider that this is a measure constant welding that you can perform 10 minute period of time( as is the standard used in the USA and Canada). Imagine having to sit idle for 9 minutes and 50 seconds after completing a 10 second weld before you start your next 10 second weld!