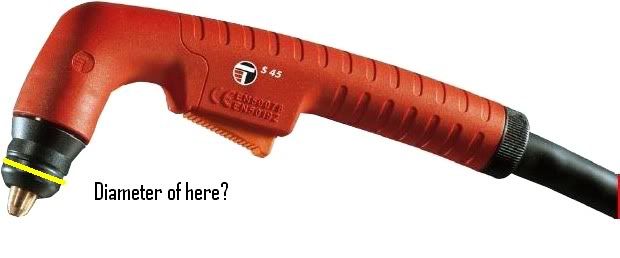

Does anyone have the diameter of this part of the plasma torch. I will probably be ordering a multiprocess welder and I will be wanting to make a circle cutter but I need to know the diameter of this part.

Not the indentation part the large outter diameter. Thanks.

Reply With Quote

Reply With Quote